How To Make Stainless Steel Cable Waterproof Joints Highly Waterproof

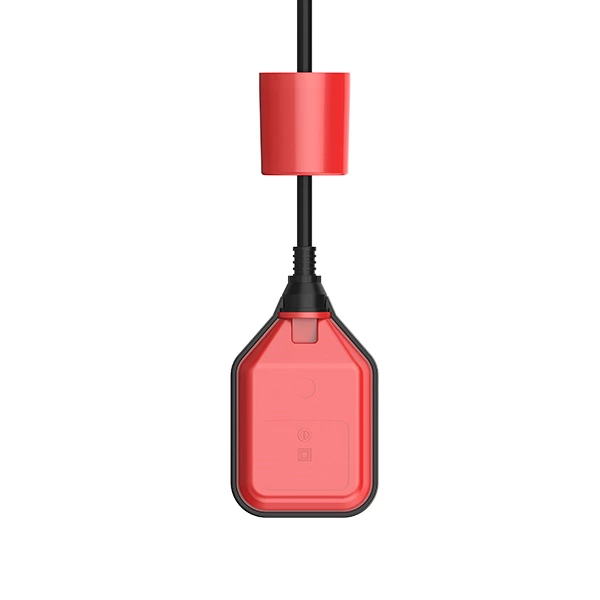

In various electrical equipment, cables are the main connecting lines, carrying the transmission task of hundreds, thousands or even tens of thousands of volts in electrical equipment. However, since the cable connection is easily affected by moisture, rust or damage, stainless steel cable waterproof connectors are used when laying cables to protect the connection security of the cable connection and prevent the cable from being corroded by rain or other liquids, thereby protecting the electrical equipment from working safely and effectively. So how can this connector be highly waterproof?

1. Make careful decisions on material selection. Stainless steel materials need to be able to withstand extreme climates such as humidity, cold and high temperature, and also need to have anti-corrosion properties.

Plastic materials used in connectors also need to pay attention to their waterproof and anti-aging properties to ensure that the connectors are not easy to age or deform, so as to achieve good waterproof effects.

2. Structural design is also very important. In order to ensure that stainless steel cable waterproof connectors can work normally in high humidity and bad weather environments, designers need to pay close attention to the capacity, sealing and connection methods of the connectors. At the same time, the connection of the connectors also requires the formulation of supporting tools and processes to make the connection tighter.

3. In order to ensure the quality of the connection, a standard inspection procedure should be adopted in the production of the joint to ensure that the accuracy and quality of each joint meet the modern power safety standards.

Practice has proved that if the materials, design and production process are comprehensively considered, the joints can prevent leakage as much as possible, so they have long-term benefits in modern power safety. They can be used in harsh environments to protect the reliability and stability of the power grid.

During installation, it is necessary to carefully check whether the various parts of the stainless steel cable waterproof joint are intact to ensure that the installation will not affect the work of the cable. At the same time, it is also necessary to pay attention to the correct use of the joint to avoid operational errors and improper use that cause damage to the joint.

In terms of maintenance, the joint needs to be checked regularly, and the parts should be replaced in time if they are damaged to avoid affecting the stability and long-term service life of the cable connection.

During use, it is also necessary to frequently check the condition of the cable connection point, clean up dust and debris in time to ensure the regional condition and effect of the connection point, and use special electrical cleaning materials to ensure that its surface is neat and beautiful.

The high-efficiency waterproof Nylon Cable Gland is very particular about materials, design and production. Only by selecting high-quality materials, reasonable structural design, mature production process and strict inspection system can we ensure that the joint has high-efficiency waterproof function. It is recommended to choose a joint produced by a reliable manufacturer to ensure the waterproof performance of the joint during use.

English

English اللغة العربية

اللغة العربية Español

Español Français

Français Português

Português Русский

Русский